|

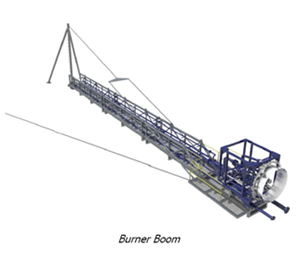

BURNER BOOM The Burner is employed during an offshore well test operation to efficiently combust oil products at surface in order to avoid oil storage and minimize pollution problems. Burners are installed on 30 to 90 feet long booms to reduce heat radiation to the offshore installation and keep flares at a safe and comfortable distance. ▬ Air line for efficient combustion, The boom is installed on the rig with a king post, base plate and guy lines.

TECHNICAL SPECIFICATIONS Working Pressure: 1,400-psi

|

|

|

| ŠAll Rights Reserved FirstSource Integrated Energy Services | home • about us • services • board • contacts |